customize your solutions request a quote right now!

Material Application: Diverse Applications

Product: 1070 aluminum foil

Project Details:

In the field of electronic component manufacturing, 1070 capacitor foil has become a core material for electrolytic capacitor production due to its excellent conductivity, corrosion resistance, and high plasticity. As electronic devices trend toward miniaturization and higher performance, the demand for flexible sizing in capacitor foils has grown significantly. So, does 1070 aluminum foil support custom dimensions, and how does its tailored service meet industry needs?

The ability to customize dimensions is one of the key advantages of this high-performance foil. While standard-sized aluminum foils often fall short in covering all application scenarios, custom solutions address this challenge. For instance, compact electronics may require thinner foils to reduce volume, while industrial-grade capacitors might need wider foils to enhance production efficiency. By adjusting thickness (e.g., 0.018mm to 0.2mm) and width (e.g., 200mm to 1550mm), the foil can accommodate diverse needs—from consumer electronics to new energy equipment. This flexibility not only improves material utilization but also helps optimize product performance.

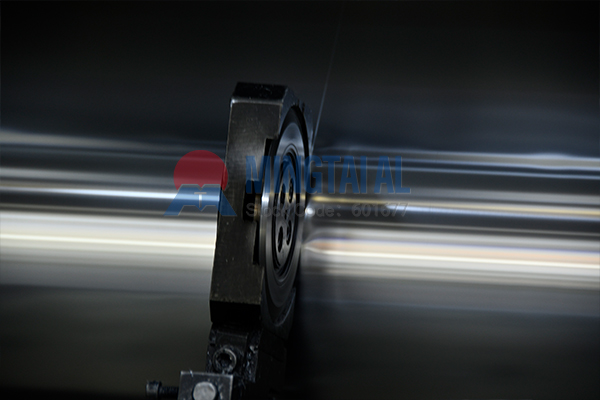

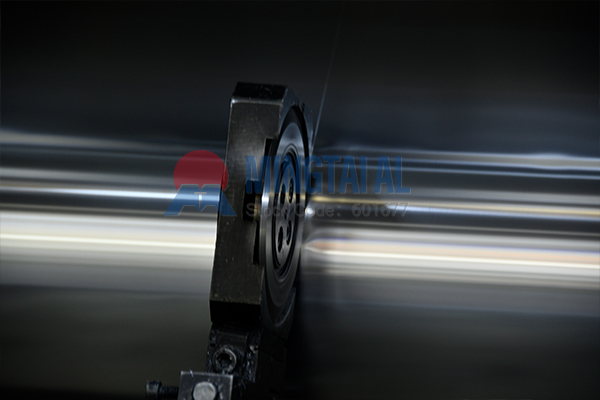

Achieving precise dimensions relies on advanced manufacturing techniques. Custom services typically include slitting, annealing, and surface treatment. For example, precision slitting ensures millimeter-level accuracy in width, while annealing enhances ductility, preventing cracks or deformation during further processing. Additionally, surface treatments (e.g., cleanliness control) improve compatibility with electrolytes, extending capacitor lifespan. These integrated processes guarantee the quality of customized foils.

The tailored solutions have been validated across multiple sectors. In smartphone battery capacitors, ultra-thin foils increase energy density, while wide-width foils (e.g., 1500mm) boost productivity in EV inverter capacitors. One global brand reduced capacitor volume by 30% without compromising performance by adopting customized foils. These cases demonstrate that customization is not just about sizing—it’s a catalyst for innovation.

For businesses seeking high-quality capacitor foils, Mingtai Aluminum offers comprehensive customization, including adjustable thickness, width, length, and surface finish. Equipped with advanced technology, they ensure dimensional precision and stability, supporting both small-batch trials and mass production to help clients stay ahead in the market.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

How to Get a Fair 8011 Aluminum Foil Price Quote Get Specs & Solutions for Aluminum Semi Rigid Container Foil Aluminum Foil for Cold Chain: Insulation and Barrier Tips Purchasing Food Safe Aluminum Foil Jumbo Rolls? 5 Key Factors for You Top Questions to Ask an Aluminum Foil Supplier How does 8011 aluminum foil vs pure aluminum foil differ? Why Choose 3004-H18 Aluminum Foil for Structural Strength? How laminated packaging material 8011 Al foil preserves food?

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.