customize your solutions request a quote right now!

Material Application: For different food containers applications,such as dishes,plates,trays ect

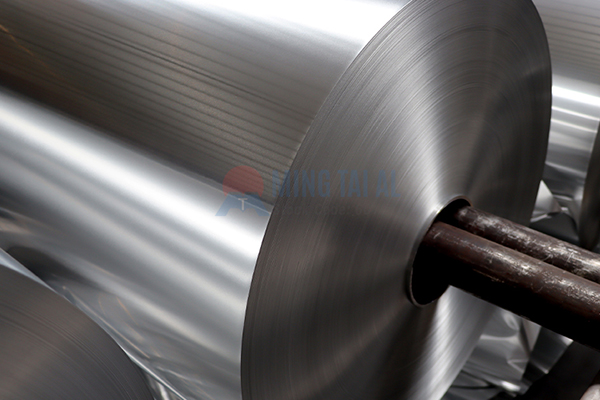

Product: 3004 aluminum foil

Project Details:

In today's consumption era that prioritizes efficiency, safety, and sustainability, packaging for food, catering, and specialty products faces unprecedented challenges: How to achieve preservation for months or even years? How to ensure absolute hygiene and safety during transportation and storage? How to design packaging that enhances brand image while adapting to high-speed automated production lines? The answer often lies in the most fundamental material. Aluminum Semi Rigid Container Foil is precisely this key foundational material that combines outstanding performance with efficient production, having become an indispensable core choice in the high-end packaging sector. Meeting these demanding application requirements places extremely high performance standards on the aluminum foil substrate.

"Semi-rigid" precisely defines the physical characteristics of this type of aluminum foil: it possesses sufficient stiffness to maintain container shape while having good plasticity to withstand deep drawing and forming without rupture. This critical balance stems from its material science and precision manufacturing processes.

1. Excellent Barrier Properties: Provides an almost 100% comprehensive barrier, completely blocking light, oxygen, moisture, and microorganisms, forming the physical foundation for ensuring long-term food preservation and preventing spoilage.

2. Superior Formability and Strength: Through specific alloys and heat treatment processes, it remains intact during deep drawing. The formed container then exhibits good pressure resistance and anti-deformation capability, meeting the needs of automated production and transportation.

3. Efficient Heat Sealability and Thermal Conductivity: Its surface readily forms strong heat seals with lidding materials, ensuring seal integrity. Simultaneously, aluminum's rapid heat conduction allows it to adapt well to various temperature scenarios, from freezing to reheating.

4. Safety and Sustainability: It inherently complies with food contact safety standards, and aluminum is 100% recyclable, making it an environmentally friendly, green material choice.

* Ready-to-Eat Food and Takeout Containers: From airline meal boxes to premium takeout lunchboxes, and the increasingly popular prepared meal containers, the requirements are deep-draw formability, sealed freshness retention, and direct heatability. This demands aluminum foil with both good deep-drawing performance and stable heat resistance.

* Bakery and Pastry Packaging: Products like tart trays, cake cups, and pie plates require foil that can form intricate patterns and maintain shape, while blocking grease and moisture to keep pastries crisp or moist.

* Dairy and Fat Packaging: Butter dishes and cheese containers require extremely strong light and oxygen barrier capabilities to prevent fat oxidation and rancidity, preserving the product's original flavor and nutritional value.

* Specialty Packaging Fields: Customized aluminum container solutions are increasingly used in areas with extreme safety and barrier requirements, such as pet food and pharmaceutical blister packs.

For procurement and R&D personnel, understanding the following core metrics is key to making the right choice:

1. Alloy Designation and Temper: Common alloys like 8011 and 3003 are widely used for their good formability and strength. The temper (e.g., H14, H24) directly determines the foil's hardness and forming depth, which must be selected based on the specific container design.

2. Thickness and Thickness Uniformity: Thickness (typically ranging from 70-150 microns) directly affects container strength and cost. Thickness uniformity is a core indicator of a manufacturer's process level, directly determining the yield rate during stamping and forming, preventing localized cracking.

3. Mechanical Properties: Tensile strength and elongation are direct data guarantees for ensuring smooth forming processes and finished product strength. Authoritative test reports should be requested from suppliers.

4. Surface Properties: The classic structure of one bright side and one matte side, or customized surface cleanliness and tension values based on subsequent processing needs (like coating, printing).

5. Certifications and Standards: Ensure the product possesses food-grade safety certifications issued by authoritative bodies and comprehensive heavy metal migration test reports.

Selecting a reliable aluminum foil supplier is the first step towards packaging success. Mingtai Aluminum specializes in the R&D and manufacturing of high-quality aluminum foil for many years. Our container foil offers global customers a solid packaging base material with exceptional stability, consistent forming performance, and strict food-grade safety standards. To obtain samples or discuss customized solutions, please feel free to contact us via our official website.

A: The core differences lie in material and performance. Container foil uses specific alloys, is thicker (usually >70 microns), and is heat-treated to a "semi-hard" temper to achieve the balance of strength and elongation required for deep drawing. Household foil is thinner, softer, and primarily used for wrapping; it cannot be deep-drawn.

A: Thickness depends on container size, depth, shape complexity, and content requirements. Generally, small shallow cups use 70-90 microns, while large deep trays may require 120 microns or more. Providing design drawings or samples allows our technical team to offer precise recommendations.

A: We supply base foil with excellent surface cleanliness and adhesion, ideal for coating and printing by downstream specialized factories. To ensure optimal results, subsequent coating/printing processes are recommended to be handled by professional converters.

A: Yes. We support customization of coil width, alloy composition, and performance parameters within reasonable ranges. Specific solutions require joint discussion based on your technical specifications.

RELATED PRODUCT

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

Get Specs & Solutions for Aluminum Semi Rigid Container Foil Aluminum Foil for Cold Chain: Insulation and Barrier Tips Purchasing Food Safe Aluminum Foil Jumbo Rolls? 5 Key Factors for You Top Questions to Ask an Aluminum Foil Supplier How does 8011 aluminum foil vs pure aluminum foil differ? Why Choose 3004-H18 Aluminum Foil for Structural Strength? How laminated packaging material 8011 Al foil preserves food? How Does Aluminum Foil for Electronics Shielding Work?

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.