customize your solutions request a quote right now!

Material Application: Building Facades

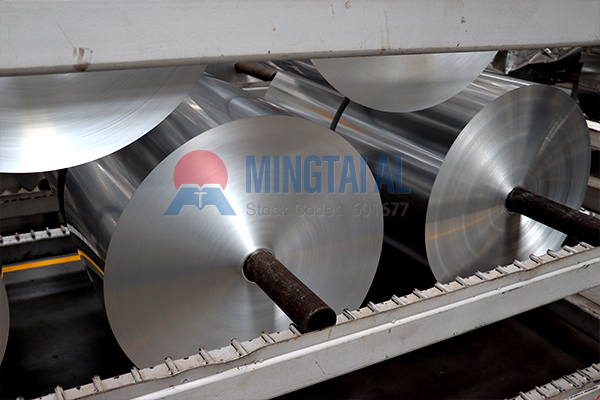

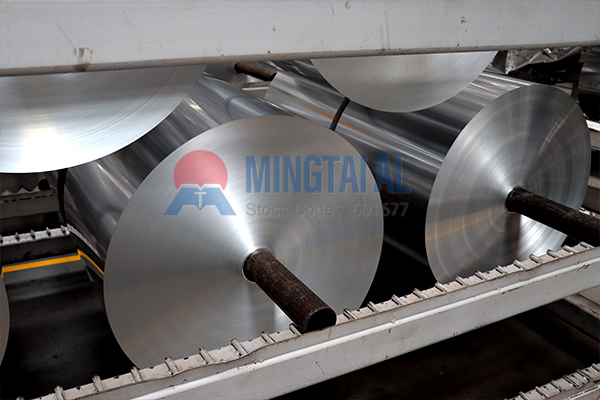

Product: 3004-H18 Aluminum Foil

Project Details:

Honeycomb aluminum panels are widely used in building facades, vehicle and ship decoration, furniture, and other fields due to their lightweight nature, high strength, and rigidity. The core layer of an aluminum honeycomb panel consists of a hexagonal honeycomb structure, formed by bonding and stretching multiple layers of 3004-H18 aluminum foil into a regular hexagonal pattern. These densely packed, interlocking cells act like numerous small I-beams, effectively distributing pressure from the panel surface, ensuring uniform force distribution and maintaining high flatness even across large areas.

The honeycomb core is typically made from 3004 aluminum foil, known for its superior strength compared to 3003 alloy. This foil resists deformation during processing, offers a smooth end surface, burr-free edges, and exceptional flatness. As an alloy-based material, it has low density and lightweight properties, making it ideal for weight reduction in applications such as high-rise building facades and vehicle interiors. The H18 temper indicates that the foil has undergone specific work hardening, providing excellent mechanical properties to meet the demands of honeycomb cores in complex environments.

The price of 3004 aluminum foil is generally determined by the aluminum ingot price plus processing fees. Since ingot prices fluctuate daily, quotations vary accordingly. Different manufacturers source materials from different suppliers, leading to variations in product quality and pricing.

Manufacturers differ in technical expertise and equipment capabilities, which directly impact the quality and performance of 3004 aluminum foil. Advanced production techniques and machinery yield higher-quality foil that meets stricter standards.

Direct sales from manufacturers eliminate middlemen, offering cost advantages to customers. This streamlined approach improves efficiency and ensures competitive pricing for high-quality products.

Established in 1997, Mingtai Aluminum has dedicated over two decades to mastering aluminum processing, earning a strong industry reputation. The company produces 3004-H18 aluminum foil for honeycomb cores, along with 3003 and 5052 foils, backed by extensive experience and a complete production line.

Mingtai Aluminum ensures strict quality control, delivering 3004 foil with superior flatness, excellent formability, high strength, and resistance to deformation. Its clean, oil-free surface enhances adhesive bonding, preventing detachment. These advantages make Mingtai’s 3004-H18 aluminum foil a preferred choice in the market, guaranteeing the quality of honeycomb panels and driving industry advancements.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

Get Specs & Solutions for Aluminum Semi Rigid Container Foil Aluminum Foil for Cold Chain: Insulation and Barrier Tips Purchasing Food Safe Aluminum Foil Jumbo Rolls? 5 Key Factors for You Top Questions to Ask an Aluminum Foil Supplier How does 8011 aluminum foil vs pure aluminum foil differ? Why Choose 3004-H18 Aluminum Foil for Structural Strength? How laminated packaging material 8011 Al foil preserves food? How Does Aluminum Foil for Electronics Shielding Work?

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.