customize your solutions request a quote right now!

Material Application: Food container

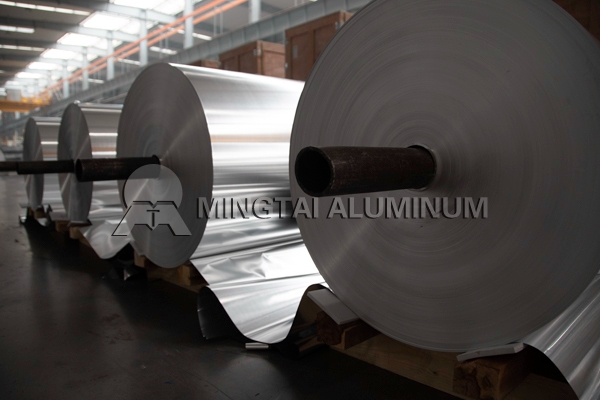

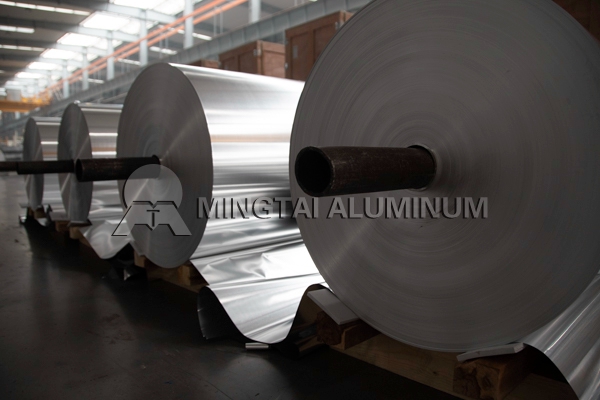

Product: 3004 aluminum foil, 8011 aluminum foil

Project Details:

Lubricated aluminum foil is a type of aluminum foil that has been coated or treated with a lubricating substance. The lubrication helps reduce friction and improve the performance of the foil in certain applications.

Lubricated aluminum foil is commonly used in the food packaging industry. The lubrication helps prevent the foil from sticking to the food or itself, making it easier to wrap or package various food items. It is often used for wrapping candies, chocolates, butter, cheese, and other similar products.

Lubricated aluminum foil offers improved handling and performance characteristics compared to regular aluminum foil, making it a preferred choice in specific applications where reduced friction is desired.

Aluminum alloys used for food containers are specifically designed to meet the requirements of packaging applications in the food industry. These alloys are chosen for their combination of properties such as strength, formability, corrosion resistance, and compatibility with food.

The most commonly used aluminum alloy for food containers is aluminum alloy 3004. It is an alloy that consists primarily of aluminum, with small additions of manganese. The addition of manganese improves the strength and formability of the alloy, making it suitable for shaping into various container shapes.

Alloy 3004 offers good corrosion resistance, which is important for food packaging applications. It forms a protective oxide layer on the surface that helps prevent corrosion and maintains the quality and safety of the packaged food.

Another commonly used aluminum alloy for food containers is aluminum alloy 8011. It is a high-strength alloy with additions of iron and silicon. Alloy 8011 provides excellent formability and is often used for making disposable food containers, such as trays, pans, and take-out containers.

Aluminum alloys such as 3004 and 8011 are the preferred choices for food container applications due to their excellent combination of properties, safety, and compliance with food packaging regulations.

Determining the quality of aluminum foil can be done by considering several factors. Here are some key aspects to consider when assessing the quality of aluminum foil:

Thickness: Check the thickness of the aluminum foil. Thicker foil tends to be more durable and resistant to tearing or puncturing.

Strength and flexibility: Quality aluminum foil should be strong and flexible. Test the foil's strength by gently manipulating it and folding it to see if it maintains its integrity.

Evenness and consistency: The foil should have a uniform thickness and be free from noticeable defects such as holes, spots, or uneven areas.

Heat resistance: Good quality aluminum foil should have adequate heat resistance.

Non-stick properties: High-quality aluminum foil often has a non-stick coating or surface treatment that prevents food from sticking to it. This feature is particularly desirable for easy food release and clean-up.

Packaging and labeling: Look for reputable brands or manufacturers that adhere to quality control standards and provide clear information about the foil's specifications, such as thickness, dimensions, and any certifications related to food safety.

Safety and compliance: Ensure that the aluminum foil complies with relevant food safety regulations and guidelines.

RELATED PRODUCT

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

How to Get a Fair 8011 Aluminum Foil Price Quote Get Specs & Solutions for Aluminum Semi Rigid Container Foil Aluminum Foil for Cold Chain: Insulation and Barrier Tips Purchasing Food Safe Aluminum Foil Jumbo Rolls? 5 Key Factors for You Top Questions to Ask an Aluminum Foil Supplier How does 8011 aluminum foil vs pure aluminum foil differ? Why Choose 3004-H18 Aluminum Foil for Structural Strength? How laminated packaging material 8011 Al foil preserves food?

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.