customize your solutions request a quote right now!

Material Application: EMI Shielding

Product: 8011,5052,6061

Project Details:

With the increasing prevalence of electronic devices, electromagnetic interference (EMI) has become a critical challenge affecting performance and stability. Aluminum foil for EMI shielding, as an efficient and cost-effective solution, is gaining widespread attention from manufacturers worldwide. This material effectively reduces signal interference between devices by reflecting and absorbing electromagnetic waves, ensuring stable operation in complex environments. As technologies like 5G and IoT advance, demand for high-performance EMI shielding materials continues to grow, with aluminum foil emerging as a preferred choice due to its lightweight, flexibility, and affordability.

The popularity of aluminum foil in this field stems from its unique physical properties. First, its excellent conductivity allows it to convert electromagnetic energy into heat and dissipate it, weakening interference signals. Second, its flexibility enables seamless adaptation to curved surfaces, making it ideal for diverse devices like smartphones, laptops, and automotive electronics. Additionally, compared to traditional metal shielding, aluminum foil is more cost-effective and easier to process, significantly reducing production costs. These advantages drive its widespread adoption.

Among alloy foils, 8011 is commonly used for its flexibility and shielding performance. The 5052 Al-Mg alloy offers moderate strength and corrosion resistance, suitable for applications requiring mechanical durability. The 6061 Al-Mg-Si alloy, with heat treatment, provides enhanced strength and machinability, meeting higher performance demands. These alloys, through tailored compositions and processes, address diverse electromagnetic protection needs.

Amid global green manufacturing initiatives, aluminum foil offers notable environmental benefits. It is 100% recyclable, and its production consumes less energy than other metals, aligning with circular economy principles. Its lightweight nature also reduces device weight, indirectly lowering transportation-related carbon emissions. For sustainability-focused brands, choosing aluminum foil not only boosts performance but also strengthens eco-friendly branding.

As technology evolves, aluminum foil’s applications continue to grow. In consumer electronics, it shields smartphones and tablets from interference during high-speed data transfer. In automotive systems, it safeguards onboard electronics for autonomous driving and IoT. Industrial and medical equipment, with stringent EMI requirements, are also adopting aluminum foil solutions. This cross-industry adoption underscores its versatility and competitiveness.

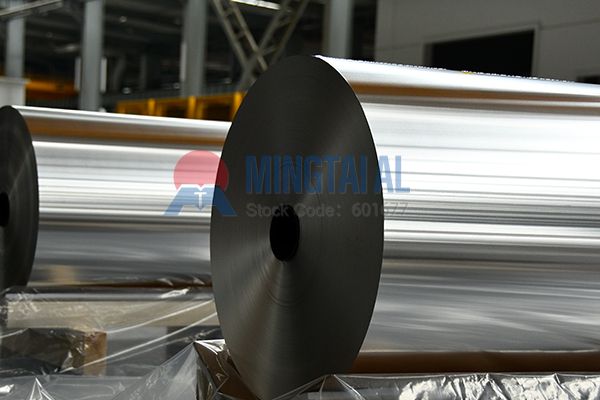

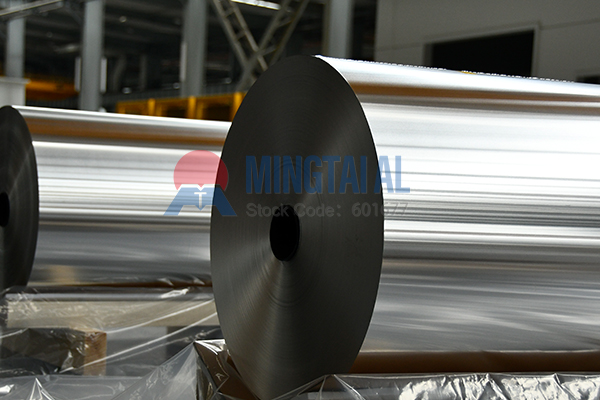

For manufacturers seeking high-quality shielding materials, Mingtai Aluminum offers specialized foil products. With years of expertise in aluminum processing, Mingtai’s EMI shielding foils excel in conductivity, flexibility, and stability, meeting customized needs. Rigorous international standards ensure reliable performance, making Mingtai the ideal partner for enhancing product competitiveness in consumer electronics and industrial applications.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

How to Get a Fair 8011 Aluminum Foil Price Quote Get Specs & Solutions for Aluminum Semi Rigid Container Foil Aluminum Foil for Cold Chain: Insulation and Barrier Tips Purchasing Food Safe Aluminum Foil Jumbo Rolls? 5 Key Factors for You Top Questions to Ask an Aluminum Foil Supplier How does 8011 aluminum foil vs pure aluminum foil differ? Why Choose 3004-H18 Aluminum Foil for Structural Strength? How laminated packaging material 8011 Al foil preserves food?

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.