customize your solutions request a quote right now!

Material Application: Construction & Industrial Maintenance

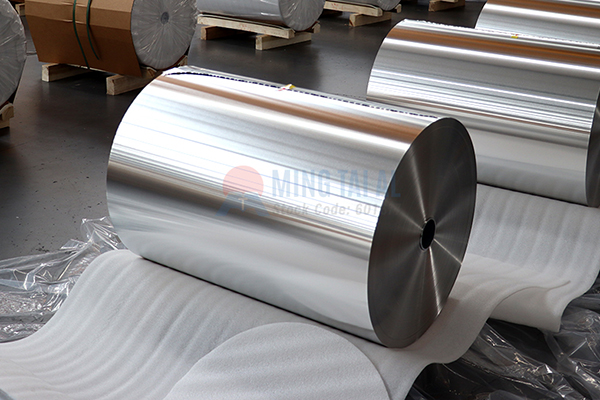

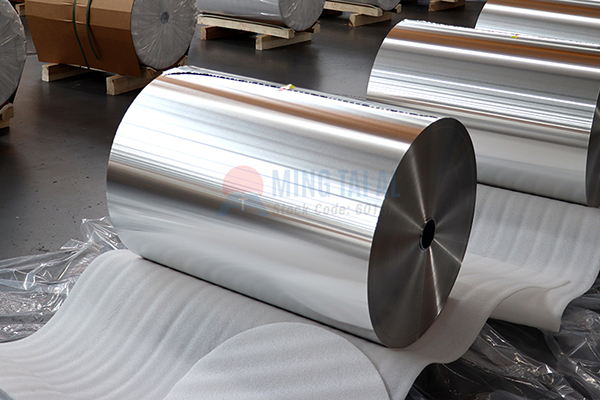

Product: 1060 or 1235 foils

Project Details:

Conductive aluminum foil, as a critical material in modern industries and daily life, is widely used in electronic devices, packaging materials, and construction due to its excellent conductivity, shielding properties, and corrosion resistance. With technological advancements, user understanding of conductive aluminum foil has expanded from basic functions to diverse applications, but systematic guidance on its proper selection and usage remains essential. This article explores the correct application methods from three perspectives: material properties, application scenarios, and selection recommendations.

The conductivity of conductive aluminum foil is closely tied to its composition. Mainstream materials include 1060 industrial pure aluminum foil, 1235 aluminum foil, and heat-resistant alloy foils containing rare earth elements. The 1060 foil, known for its high plasticity, corrosion resistance, and conductivity, is the preferred substrate for electronic capacitors, food packaging, and RFID tag antennas. Meanwhile, 1235 foil excels in elongation and surface gloss, making it ideal for adhesive tapes and electronic labels. Additionally, heat-resistant alloys with zirconium or rare earth elements (e.g., 58TA1, 60TA1) enhance high-temperature stability, proving superior in short-distance, high-capacity power transmission lines. The varying conductivity and thermal resistance of these alloys determine their specialized applications.

In smartphones, computers, and EV batteries, this material plays a pivotal role. For instance, battery electrodes leverage its high conductivity to improve energy storage efficiency, while double-sided conductive flame-retardant tapes provide electromagnetic shielding for transformers and displays.

Its barrier properties make it ideal for food and pharmaceutical packaging. Wrapping banana stems or using blister packs significantly extends freshness by blocking oxygen.

Wrapping foil around wire crossings shields AC signals, reducing electromagnetic radiation. It also aids in circuit repairs, pipe sealing, and floor protection during furniture moves.

Recyclability aligns with sustainability goals. Its oxidized surface absorbs grease for grill cleaning, while dampened foil efficiently removes rust.

For electronics, prioritize 1060 or 1235 foils for conductivity and formability; opt for zirconium-enhanced alloys in high-temperature environments like transformer cooling.

Flame-retardant conductive tapes require stable adhesives, while food-grade foils must meet FDA/EU standards to prevent harmful substance migration.

Avoiding Pitfalls

Using standard foil for EMI shielding may cause signal leakage, and untreated oily surfaces can compromise welding quality.

As a leader in China’s aluminum processing industry, Mingtai Aluminum supplies 1060, 1235, and other series, serving capacitors, cables, and electronic labels. Their foils feature flat surfaces, superior conductivity, and customizable production with lead times as short as seven days. Whether for bulk orders or small-scale customization, Mingtai delivers consistent quality and technical support.

By selecting and applying conductive aluminum foil scientifically, its full potential can be unlocked. Understanding its core properties and scenario-specific adaptability ensures optimal utility in both industrial and everyday contexts.

RELATED PRODUCT

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

How to Get a Fair 8011 Aluminum Foil Price Quote Get Specs & Solutions for Aluminum Semi Rigid Container Foil Aluminum Foil for Cold Chain: Insulation and Barrier Tips Purchasing Food Safe Aluminum Foil Jumbo Rolls? 5 Key Factors for You Top Questions to Ask an Aluminum Foil Supplier How does 8011 aluminum foil vs pure aluminum foil differ? Why Choose 3004-H18 Aluminum Foil for Structural Strength? How laminated packaging material 8011 Al foil preserves food?

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.