customize your solutions request a quote right now!

Material Application: Packaging Industry

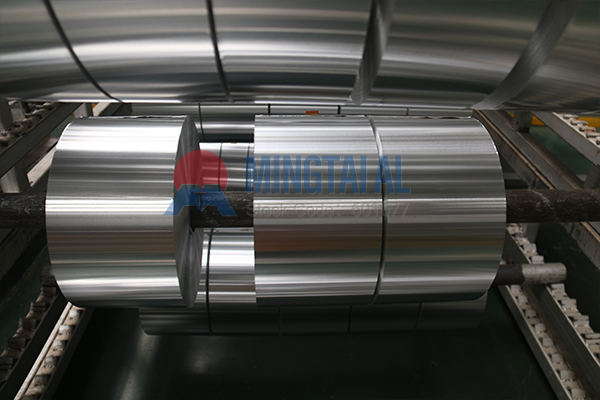

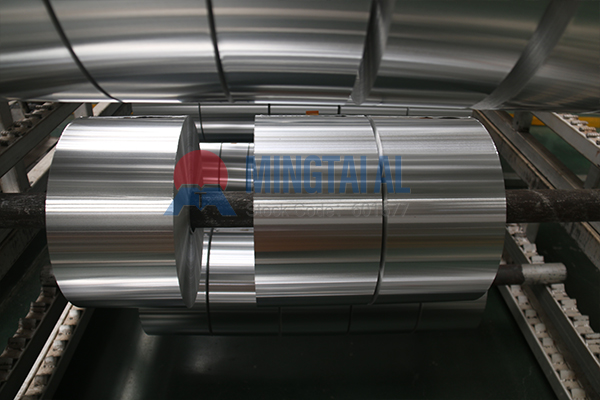

Product: 8011 Aluminum Foil

Project Details:

Aluminum foil holds a significant position in the packaging industry due to its excellent barrier properties, moisture and light resistance, as well as its safety and non-toxicity. Its highly dense metallic crystal structure effectively blocks gases, and when combined with other materials, its barrier performance is further enhanced. As a result, aluminum foil is widely used in food packaging, medical foil 8011 for packaging, and other fields. Nearly all modern packaging products requiring light-proof or high-barrier composite materials utilize aluminum foil as the barrier layer.

The most commonly used pharmaceutical packaging aluminum foils on the market include 8011 and 8021 alloys, typically in H18 or O temper. PTP (Press-Through-Pack) aluminum foil has a complex structure, consisting of a protective layer (OP), outer printing layer, aluminum base material (AL), inner printing layer, and adhesive (VC). Among these, medical foil 8011 for packaging (8011-H18) serves as the critical barrier layer, requiring high heat-seal strength, pinhole-free performance, and excellent sealing properties to ensure the safety and stability of medicines during storage and transportation.

8011 medical aluminum foil must meet strict standards in terms of chemical composition, dimensions, and appearance. Its chemical composition should comply with GB/T 3190, while thickness and width must fall within specified tolerances. The surface must be clean and smooth, free from corrosion spots and severe wrinkles, with minimal pinholes. The edges should be neat and free of burrs, dents, or damage. Additionally, the foil must unwind smoothly without sticking or tearing along its entire length.

In pharmaceutical packaging, 8011 aluminum foil demonstrates exceptional advantages. It effectively blocks light, moisture, and oxygen, preserving the chemical stability and efficacy of medicines while extending shelf life. Moreover, its superior heat-sealing performance ensures airtight packaging, preventing contamination. Being non-toxic and compliant with stringent medical packaging standards, it provides reliable protection for drug safety.

Mingtai Aluminum is a comprehensive manufacturer specializing in the R&D and production of 1xxx to 8xxx series aluminum sheets, strips, and foils. Established in 1997 as a publicly listed company, it boasts over 20 years of experience in aluminum processing. Equipped with advanced facilities, Mingtai offers strong production capabilities and customized solutions, adopting a direct-supply model with competitive pricing. Its products are exported worldwide, earning widespread acclaim for superior quality, reasonable pricing, and excellent service. Mingtai has long been a trusted supplier of high-grade medical foil 8011 for packaging to domestic and international pharmaceutical companies.

For more information about 8011 aluminum foil, please call +86 177 3712 6910.

Hot Sale Products

Aluminum foil for takeout containers Aluminum foil for cosmetic bottle caps Lidding aluminum foil Aluminum foil for sealing gasket Cable Aluminum Foil 6061 aluminum foil Milk Powder Can Lid Aluminum Foil

Solutions

How to Get a Fair 8011 Aluminum Foil Price Quote Get Specs & Solutions for Aluminum Semi Rigid Container Foil Aluminum Foil for Cold Chain: Insulation and Barrier Tips Purchasing Food Safe Aluminum Foil Jumbo Rolls? 5 Key Factors for You Top Questions to Ask an Aluminum Foil Supplier How does 8011 aluminum foil vs pure aluminum foil differ? Why Choose 3004-H18 Aluminum Foil for Structural Strength? How laminated packaging material 8011 Al foil preserves food?

Quick Contact

Copyright © 2022 Mingtai Aluminum All Rights Reserved.